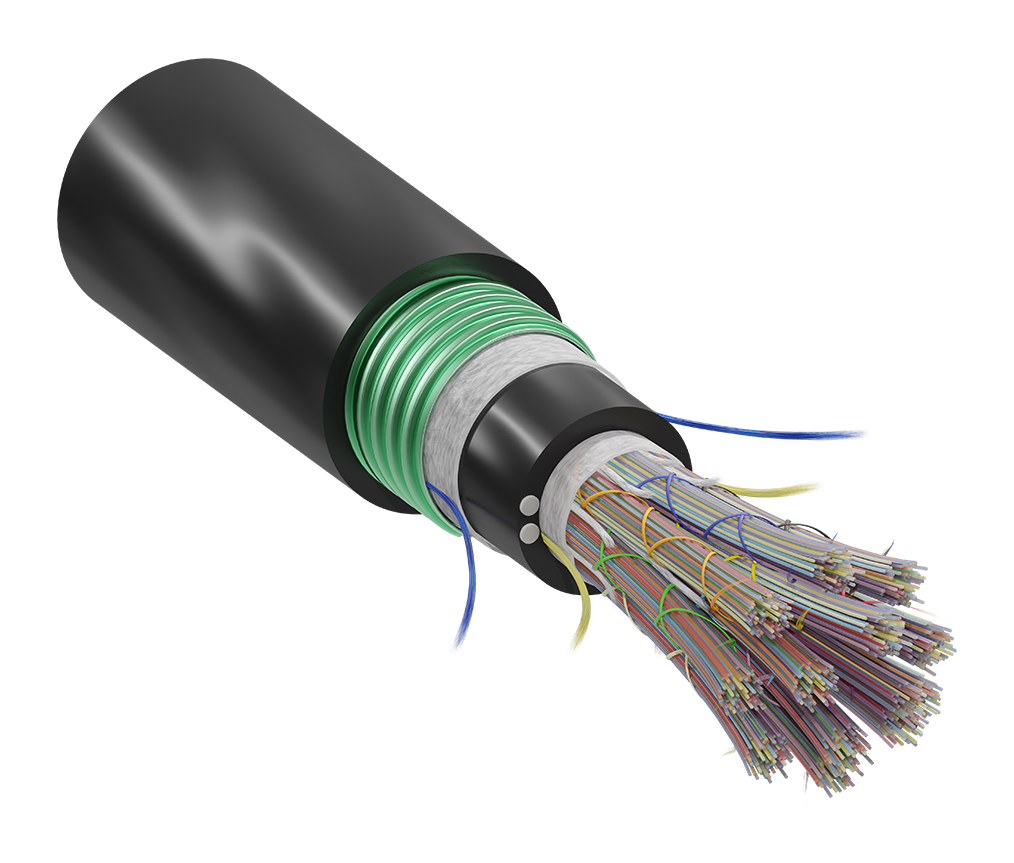

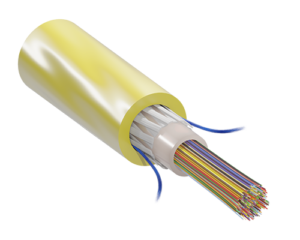

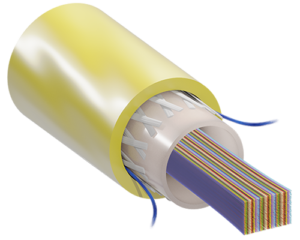

Freeform Ribbon™ Armored Monotube OSP Cable

Sumitomo Electric Lightwave’s Freeform Ribbon™ Armored Monotube Outside Plant (OSP) Cable is intended for duct installation, and the patented 12-fiber pliable Freeform Ribbon™ is constructed of 250 μm color-coded optical fibers. Freeform Ribbon™ enables high fiber density within a small cable diameter, which in turn helps with limited duct space. The 12-fiber ribbons may be spliced to a conventional ribbon, pliable ribbon, or non-ribbonized (single) fibers, as well as connectorization with both MPO and all industry standard connectors. These cables feature a dry water block yarn design that eliminates cable flooding gels, thereby eliminating the cleaning and blocking preparation steps associated with standard gel-filled cables. The steel-armored sheath construction produces a rugged, rodent-resistant cable and adds the compressive strength required for direct buried applications.

Product Downloads

Specifications

| General | |

|---|---|

| Application | Outside Plant |

| Jacket Color | Black PE |

| Cable Structure | Monotube |

| Ribbon Type | Freeform Ribbon™ |

| Metallic Elements | Bonding/Grounding Required |

| Fiber | |

|---|---|

| Fiber Type | PureBand™-R G.657.A1 Bend Insensitive Single-Mode Fiber |

| Fiber Attenuation Grades | Standard Single-Mode |

| Mode Field Diameter | 1310 nm | 9.2 +/- 0.4 μm |

| Maximum Attenuation | 1310 nm | 0.40 dB/km 1550 nm | 0.30 dB/km |

| Mechanical Characteristics | |

|---|---|

| Max. Tensile Load (During Installation) | 600 lb (2,670 N) |

| Max. Recommended Service Load | 180 lb (800 N) |

| Maximum Compression Resistance | 124 lb/in (220 N/cm) |

| Bend Radius | |

|---|---|

| During Installation | 20 x Cable OD |

| After Installation | 15 x Cable OD |

| Temperature Range | |

|---|---|

| Operation | -40 to +158°F (-40 to +70°C) |

| Storage & Shipping | -40 to +158°F (-40 to +70°C) |

| Installation | -22 to +140°F (-30 to +60°C) |

| Standards | |

|---|---|

| Standards | Referencing Telcordia GR-20 |

Ordering Information

| Part Number | Fiber Size | Fiber Count | Nominal Cable OD (in / mm) | Nominal Weight (lb/kft | kg/km) | Fibers Per Ribbon | No. of Bundles |

|---|---|---|---|---|---|---|

| SE-CMBP0864-C | 250 μm | 864f | 0.91 (23.0) | 302.0 (450.0) | 12f | 12 |

Accessories

| Part Number | Description |

|---|---|

| CRC-001 | Cable Ring Tool, 0.25 – 1.625 in (4 – 28 mm) for End/Mid-Span Access |

| CSC-002 | Cable Slit Tool for End/Mid-Span Access |

| ACS-01 | Armored Cable Slit & Ring Tool, 0.315 – 1.125 in (8 – 28.6 mm) for End/Mid-Span Access |

| ACS-01-BLADE | Replacement Blade for ACS-01 |

| FRSJ-01 | Freeform Ribbon™ Separation Tool Kit |

| MA-2-REFILL | Ribbon Matrix Remover with Board & Double-Sided Tape (Qty. 25) |

| JR-7 | Heated Jacket Remover with AC Adapter & Battery for Single Fibers & Up to 12-Fiber Ribbons |

| JR-M03 | Jacket Remover for 250 μm, 900 μm, and up to 3 mm Jacketed Single Fibers |

| LYNX-SHEARS | Lynx-CustomFit™ Aramid Shears |

Features

- Patented Pliable Freeform Ribbon® Color-Coded Optical Fibers

- PureBand™-R Bend Insensitive Single Mode Fiber G.657.A1

- Gel-free, Water-blocking Tape

- Meets Requirements of 60793-1, 60793-2, 60794-1

- Tested Per Applicable Requirements of Telcordia GR-20

Benefits

- Quick And Easy Fiber Identification

- Robust In Harsh Installation Environments

- Robust in Outdoor Environments

- High Fiber Density Maximizes Duct Space

- Compatible With Mass and Single Fiber Fusion Splicers, Splice-On Connectors & Hardware

- Armor Adds Additional Protection