Blowing Head Equipment & Accessories

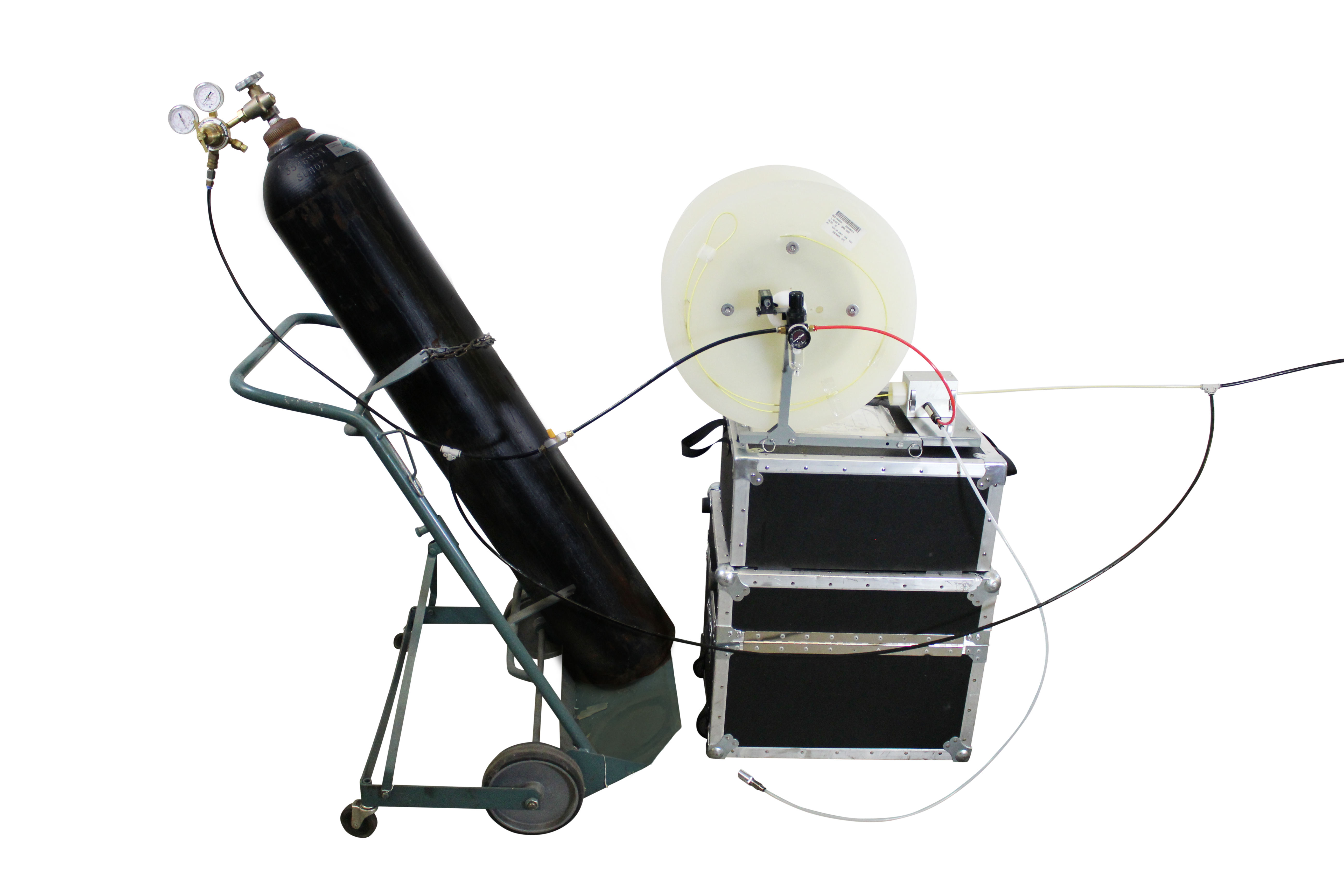

Sumitomo Electric Lightwave’s cable blowing head is used to blow the compact fiber optic bundles through the tube cable on a stream of air or nitrogen gas. Installation is completely stress-free, eliminating the damage that can occur when traditional fiber is pulled through the network.

Product Downloads

Kitting Components

| COMPONENT |

|---|

| Pressure Regulator Assembly with male quick-release 8mm Tubing Adapter. Part-Number: BEREG02 |

| Filter/Regulator Assembly with Payoff Counter |

| 2 ft Length of Red ¼ inch Tubing |

| 6 ft Length of White ¼ inch Tubing |

| 1 ft Length of 8 mm Clear Tubing |

| ½ inch x 14 inch Steel Shaft |

| Toolbox |

| Motor Rate Control Valve with 8 mm Fittings |

| Exhaust Muffler |

| Reel Payoff Cams |

| Fiber Bundle Guide Assembly (Two Halves) |

| Fiber Bundle Drive Wheels for Installing 2 mm OD Fiber Bundles (BE02DW); Consumable Items |

| Fiber Bundle Drive Wheels for Installing 3 mm OD Fiber Bundles (BE03DW); Consumable Items |

| Air Seal for Installing 2 mm OD Fiber Bundles (BE02SL) |

| Air Seal for Installing 3 mm OD Fiber Bundles (BE03SL) |

| Air Seal for Installing 3.7 mm OD 48-Fiber Bundles and 4.0 mm OD 72-Fiber Bundles (BE04SL) |

| Fiber Bundle Blowing Tip for Installing 2 mm OD Fiber Bundles (BE2MFT) |

| Fiber Bundle Blowing Tip for Installing 3 mm OD Fiber Bundles (BE3MFT) |

| Fiber Bundle Blowing Tip for Installing 48 & 72 Fiber Bundles (BE35MFT) |

| Tubing Cutter (BETC001) |

| Tee Couplings (DE08MT) |

| Allen Wrenches (³⁄₃₂ in and ⁷⁄₆₄ in) |

| Air Motor Cleaner Fluid (⅓ fl oz) |

| Instructions and Inventory Sheet |

Ordering Information

Blowing Head Rental Kits

Blowing head kits are leased only to Sumitomo Electric Lightwave licensed installers.

| Part Number | Description |

|---|---|

| BE200LRM | Blowing Head Kit, Monthly Rental |

| BE200LRS | Blowing Head Kit, Semi-annual Rental |

| BE200LRY | Blowing Head Kit, Yearly Rental (Long Reel for 72-Fiber Bundle and/or Fiber Bundle Extended Length) |

Blowing Head Accessories

| Part Number | Description |

|---|---|

| BE200LRM | Blowing Head Kit, Monthly Rental |

| BE200LRS | Blowing Head Kit, Semi-annual Rental |

| BE200LRY | Blowing Head Kit, Yearly Rental (Long Reel for 72-Fiber Bundle and/or Fiber Bundle Extended Length) |

| BE02DW | Blowing Head Drive Wheels 2, 4 or 6 and 12-Fiber Single Sub-unit Bundle / Red |

| BE02SL | Blowing Head Seal 2, 4 or 6 and 12-Fiber Single Sub-unit Bundle / Black |

| BE03DW | Blowing Head Drive Wheels (12 Legacy, 18, 24, 48 or 72-Fiber Bundle) / Black |

| BE03SL | Blowing Head Seal (12 Legacy, 18 or 24-Fiber Bundle) Black |

| BE04SL | Blowing Head Seal (48 and 72-Fiber Bundle) Black |

| BE08CTB | BB Catcher with 8mm Fittings |

| BE2MFT | Reusable, threaded, aluminum tip for installing 2, 4 or 6 and 12-Fiber Bundle/Red |

| BE3MFT | Reusable, threaded, aluminum tip for installing for 24-Fiber Bundle/Black |

| BE35MFT | Reusable, threaded, aluminum tip for 48 and 72-Fiber Bundle/Green |

| BEPT001 | Tube Testing Kit, for Pressure & Obstruction Tests |

| BEPT0S | Pressure Test Switch |

| BEBB01P | 5 mm Plastic Beads (for Obstruction Testing) pack of 100 |

| BEPTGA | Test Gauge – Handheld Pressure Gauge with 8 mm Fitting for Tube Pressure Testing |

| BEBB40P | 4 mm Plastic Beads (for Obstruction Testing of TCxxTP2 series) |

| BEREG02 | Single-Stage Nitrogen Tank Regulator, 0-200 psi |

| BEISOV1 | Dual-Tank Isolation Valve Kit – for using 2 nitrogen bottles |

| BEREGCA | Regulator adapter for compressed air cylinders |

| BETC001 | Tube Cutter |

| BETC00B | Replacement Blade for Tube Cutter |

| BETLL03 | Tube Cable Cutter (Replaced BETL01 and BETL02) |

Minimum order quantities may apply. Please contact Inside Sales for further information.

Resources

| Sumitomo Recommended Procedure |

|---|

| SP-F04-001: Blowing Equipment Set-up Procedure |

| SP-F04-026: Tandem Blowing Procedure for Multiple Blowing Heads |

| SP-F04-027: Mid-Span Blowing with a Figure 8 Procedure |

| SP-F04-028: Segment Blowing with a Figure 8 Procedure |

| LFI Resource Portal |

|---|

| LFI Resource Portal | Sumitomo Electric Lightwave Corporation |

Features

- System Consists of a Payoff Stand on Which Reels of Fiber Bundles are Placed; a Blowing Head Used to Direct the Fiber Bundles; a Pressure Regulator and Air Source

- Air Source is Either Compressed Air or Bottles of Compressed Nitrogen

- Pressure Regulator with 0-200 psi Output Pressure

- Fiber Bundles are Blown at Rates Up to 150 Feet Per Minute. Speed is Controlled by Air Flow Rate Through Motor