Network data traffic is continuously increasing, leading to the construction of more and more data centers all over the world. This demand has led to major growth in the need for Internet Service Provider (ISP) fiber cable. In response to the growth of data demands around the globe, Sumitomo Electric Lightwave (SEL) developed ultra-low-loss (ULL) multi-fiber MPO connector technology, which connects not only 24-fibers at the same time, but also provides the same characteristics as a ultra-low-loss single-fiber LC connector. In the past, such characteristics were achieved at the laboratory-level only. To date, however, SEL has successfully launched the lowest insertion loss ULL 24f MPO connector assembly available anywhere on the market.

High-fiber count connections are a rapidly expanding technology because they offer efficient installation of a data center’s fiber network. Single-fiber connectors are still often used instead of the multi-fiber option, however, because of their lower loss and reliable characteristics. According to the Optical Connector Device International Standard IEC61753-1, connector insertion loss criteria is categorized into three grades – from grade B to grade D. Currently, most data center integrators use the grade B insertion loss specification (with 0.25dB max for >97% of samples) in order to design reliable optical paths. Grade B single-fiber LC connectors are traditionally used in infrastructure because MPO has been known for higher loss than LC.

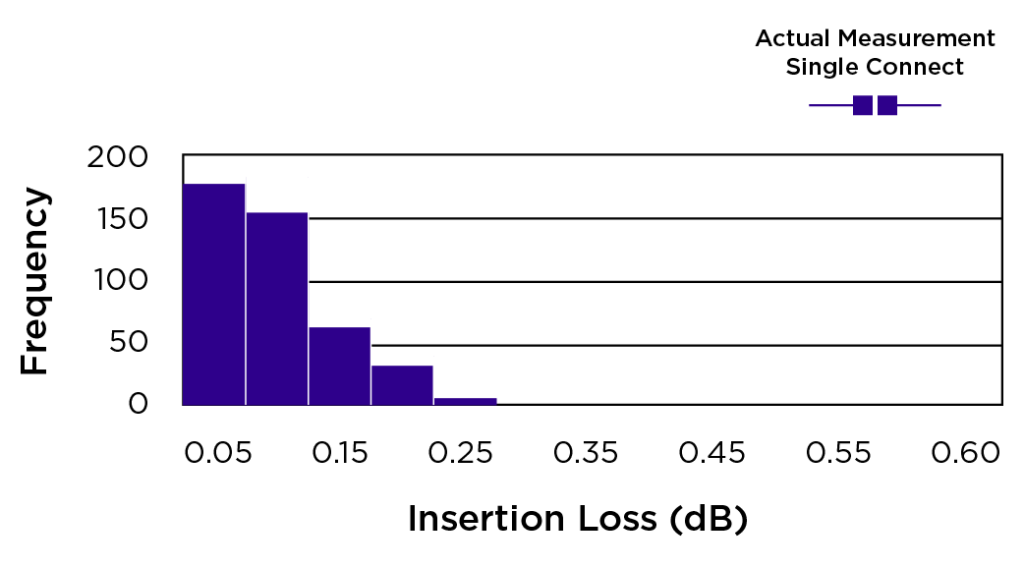

The picture below illustrates the actual test results of Sumitomo’s single-mode 24f-MPO connector insertion loss characteristics at random mating.

What are the key technologies to achieve ULL in mass production?

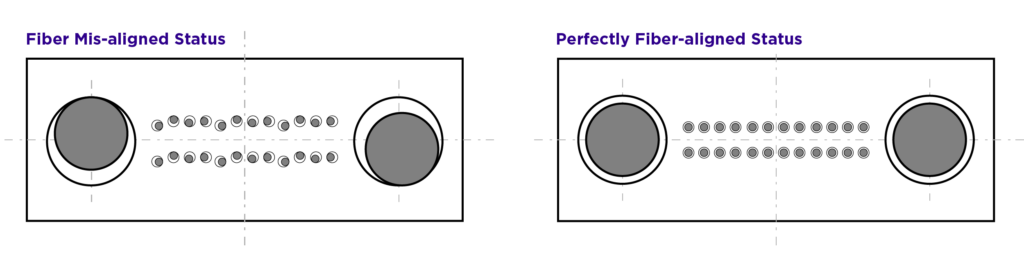

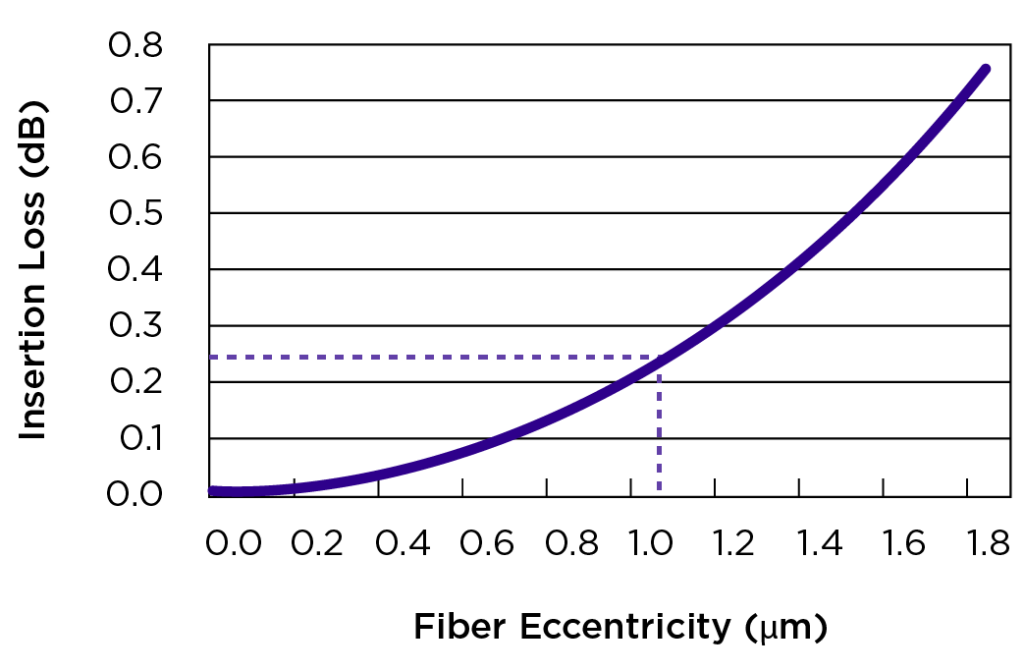

The basic idea for realizing a lower loss connector is a simple one: establish each fiber at the designated position with zero eccentricity to avoid fiber misalignment loss. However, a sub-micron level adjustment is required using a different process and materials, so realization has been challenging for general connector producers.

SEL has developed a precise mold-tooling process and material, special injection machine, precisely repeatable sub-micron measurement test equipment, specially controlled fiber, and a unique connector-termination process. SEL’s ULL MPO assembly technologies provide efficient connectivity in applications and industries throughout the world. Our experts will create custom solutions to fit every network’s needs.