With the advancement of cloud computing, the pace of construction for large-scale data centers (DCs) is rapidly increasing worldwide. As these networks process more and more data, they require an increase in transmission capacity as quickly as possible. One issue arising from this increase is that cables that connect DCs are usually installed in underground ducts with limited space and short installation timelines. This challenge has resulted in a demand for optical fiber cables with higher density which maximize duct space and minimize installation time and cost. Unfortunately, technicians who specialize in the unique splicing work required to meet these challenges are becoming rarer and rarer, especially in the United States.

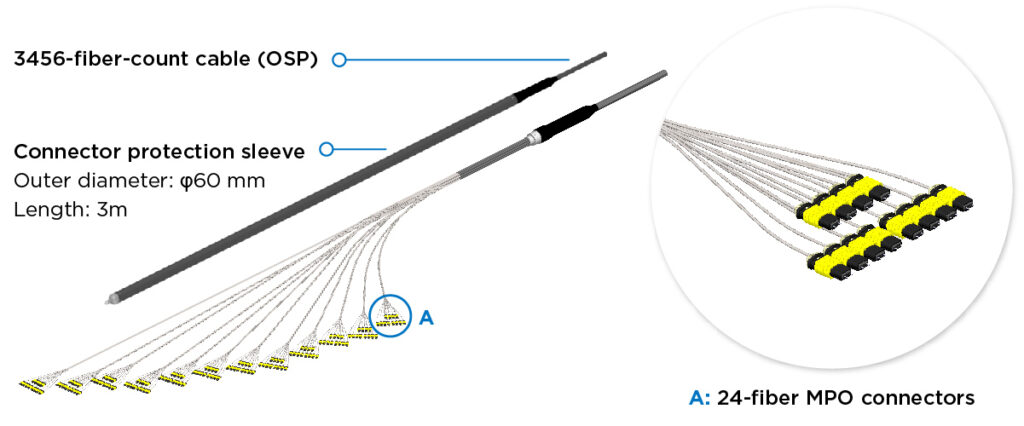

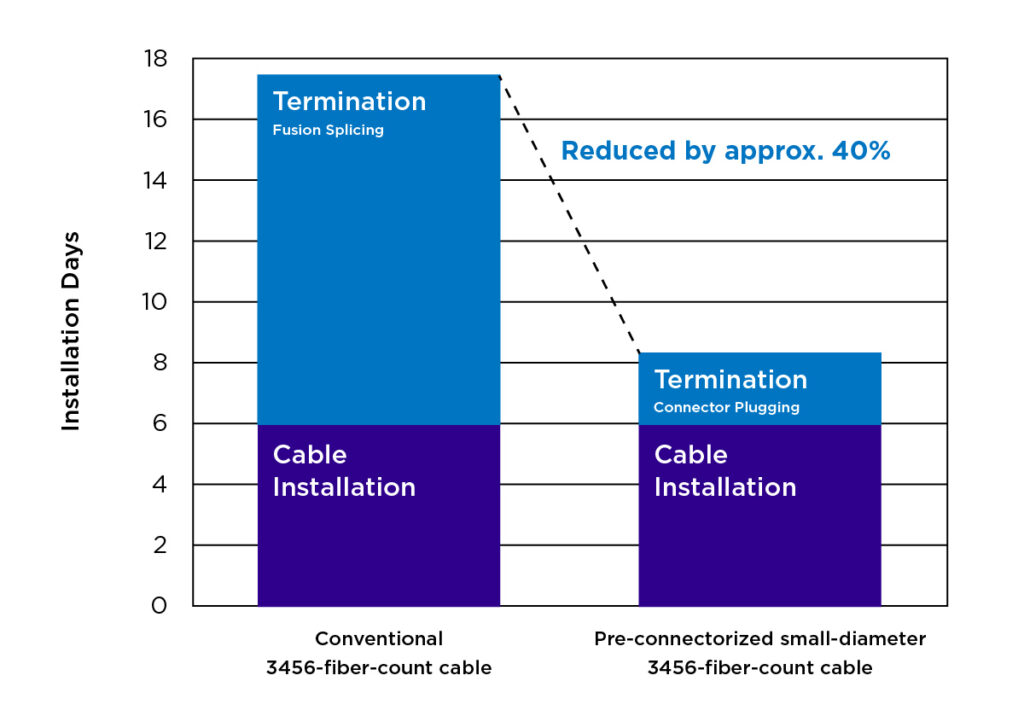

In response to these needs and challenges, Sumitomo Electric Lightwave (SEL) has developed a pre-connectorized ultra-high-fiber-count (UHFC) optical fiber cable (see Figure 1). This 3456-fiber cable uses 200 µm Freeform Ribbon™ fibers and a slotted core. At both ends of the cable, 144 pcs of 24-fiber multi-fiber push-on (MPO) connectors (with an insertion loss of <0.35dB) are fully factory assembled at each end. Because these MPOs are factory assembled, no additional connector assembly is required in the field; simply plug them into the adapters. Connectors are precisely sealed with a protection tube with a diameter of 60 mm and length of 3 meters. In order to store the 144pcs MPO connector in such a small diameter tube, the connectors are terminated in a step-length location. For ease of installation, the protection tube is made of a spiral metal tube with resin coating. This allows for the same level of the mechanical performance as the cable, such as tensile strength, compressive strength, and waterproofing. In a 4-inch inner diameter duct, three of this 3456-fiber cable can be installed, the same as conventional non-connectorized cable. It also enables a reduction of connection time by using the MPO connectors instead of mass fusion splicing and is expected to reduce installation time by about 40% compared to conventional cables.

Benefits and features of preconnectorized cables

One of the features of preconnectorized cables is durability. SEL’s evaluations confirmed excellent durability of the protective tube even under the severe conditions of 30 repeated installations. Another added benefit is that this work does not require specially-trained technicians.

Also, the use of preconnectorized 3456-fiber-count cables was shown to drastically reduce the termination time by replacing the fusion splicing with connector plugging. As a result, 40% reduction in installation time compared to conventional 3456-fiber-count cables.

Among the many time-saving benefits of preconnectorized cables, installation workability stands out. In factory tests, SEL confirmed that the cable could be installed with a pulling tension equivalent to that required for installing a conventional cable under certain conditions. And the use of preconnectorized cables drastically reduces termination time by replacing the fusion splicing with connector plugging. To reduce installation time in DCs, we have developed and commercialized pre-connectorized UHFC optical cables at both ends – the multi-fiber connectors are preassembled at plants. As a result, as mentioned in the introduction, there is a 40% reduction in installation time compared to conventional 3456-fiber-count cables.

Features and benefits of preconnectorized cables include:

- Ensures factory-loss specifications

- Quicker installations and lower total installation cost than non-connectorized

- Preinstalled ribbon breakout protection

- Easy fiber identification

- Can be 100% customized to the measurements of your project

- As durable as conventional cable installation – connectors are housed in a protective clamshell during installation, eliminating the need for concern

Learn more about the components that make up our preconnectorized cabling solution for Data Centers:

Ultra-Low-Loss MPO Connectors for Data Centers

Maximizing Data Center Duct Space with Ultra-High-Fiber-Count X-Slotted Core Cables