Enhanced splice experience

NanoTune™ reduces your time spent working and reduces splicing loss overall, by using the World’s first※1 AI splicing technology.

※1 Based on an internal investigation.

Time-saving

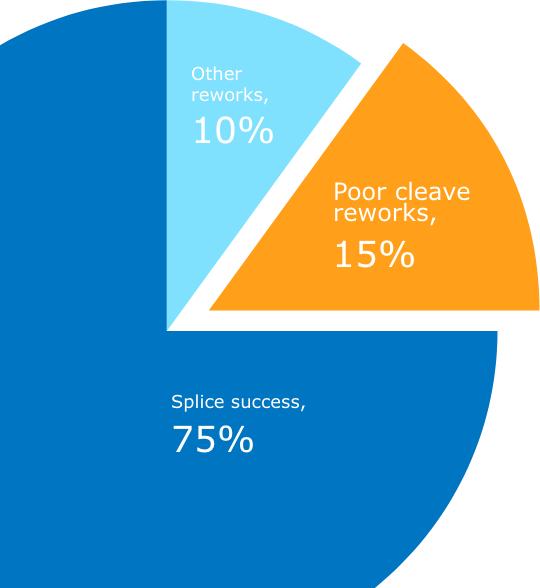

Rework, especially of fibre preparation, occasionally need to be done, even with the most skilled workers. NanoTune™ drastically reduces the need for these reworks, by being able to splice fibres that would have previously required rework. NanoTune™ realises this by using state-of-the-art technology and our unique algorithms to accurately adjust parameters when splicing.

NanoTune™ improves your field splice success rate to 90%, thus shortening your working time drastically.

5 key technologies

Glass melting technology

Mature glass melting techniques, cultivated as the pioneer in optical fibre manufacturing

Accumulated knowledge

Field data collected by the use of SumiCloud™ forms a pool of big data that is used to simulate and analyze potential problems

Cutting edge AI technology

State-of-the-art fibre end analysis technology, with AI based real-time 3D pattern recognition

Optimized algorithm

Splicing algorithm is optimized to instantly calculate the best possible splice based on 10 essential splice parameters

Prediction of core position

Fibre core position prediction technology, watching fibres until the moment of splicing

Accurate splicing

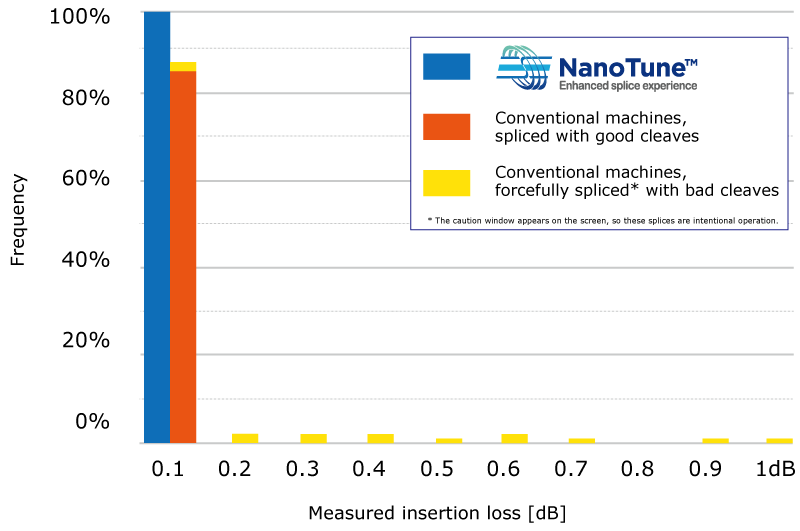

Traditional splicers alert and request rework when a bad cleave is detected to maintain good splice performance. If the alert is ignored, bad cleaves often results in bad insertion loss(yellow). NanoTune™ has improved splicing capabilities of bad cleaves, enabling splicing such fibres with low loss(blue) with the state-of-art AI technology.