Test – Fusion Splicer

The Q102-M12 is accompanied with features and benefits capable of deploying next-generation hyperscale networks. Consistent and quality low-loss splicing, the compatibility with Lynx-CustomFit™ Splice-On Connectors, and Sumitomo Electric’s patented dual independent ovens make this fusion splicer a preferred choice for extensive and diverse optical fiber networks. This ribbon fiber splicer is adaptable to 250 µm and 200 µm ecosystems, and has a wide range of accessories for various ribbon fiber splicing situations.

Specifications

| PRODUCT CLASSIFICATION | |

|---|---|

| Product Type | Fusion Splicer |

| Alignment Type | V-Groove |

| OPTICAL FIBER REQUIREMENTS | |

|---|---|

| Material | Silica Glass |

| Fiber Count | 1 – 12f |

| Profile Types | SMF(G.652), MMF(G.651), DSF(G.853), NZDSF(G.655), BIF(G.657) |

| Cladding Dia. | 125 µm |

| Coating Dia. (1f) | 200, 250, 500, 900 µm |

| Coating Dia. (12f) | 200 to 400 µm |

| Fiber pitch | 250 µm |

| Cleave Length | 10 mm |

| Applicable Drop Cable | 2.0 x 3.1 mm, or 2.6 mm |

| Applicable Indoor Cable | 2.0 x 1.6 mm |

| SPLICE LOSS | |

|---|---|

| Splice Loss (Typical) – SMF | 0.05 dB |

| Splice Loss (Typical) – MMF | 0.02 dB |

| Splice Loss (Typical) – DSF | 0.08 dB |

| Splice Loss (Typical) – NZDSF | 0.08 dB |

| Return Loss (Typical) | ≥ 60 dB |

| Proof Test | 1.96 to 2.09 N |

| Estimation Loss Type | Clad |

| Estimation Loss Technology | Standard |

| SPLICE & HEAT CYCLES | |

|---|---|

| Splice Time (Typical) – SM 12c Quick Mode | 11 Sec |

| Splice Time (Typical) – SM 12c Std. Mode | 14 Sec |

| Heating Time (Typical) – 40mm 1-12x Quick Mode | 35 sec |

| Splice & Heat Cycles Per Battery Full Charge (Approx.) | 180 |

| APPLICABLE PROTECTION SLEEVES | |

|---|---|

| FPS-6 (40 mm) | Yes |

| FSP-40 (40 mm) | Yes |

| FPS-1 (60 mm) | Yes |

| FPS-61-2.6 (61 mm) | Yes |

| Sumitomo Nano Sleeves | Yes |

| MAGNIFICATION | |

|---|---|

| Magnification (Single Axis View) | 23X |

| Zoom Magnification (Single Axis View) | 46X |

| Magnification (Dual Axis View) | 23X |

| PROGRAMS | |

|---|---|

| Splice Program Max. | 300 |

| Splice Program Pre-Optimized | 36 |

| Heating Program Max. | 100 |

| Heating Program Pre-Optimized | 33 |

| STORAGE | |

|---|---|

| Splice Image Capture (Internal Memory) | 200 Images |

| Splice Data Storage (internal memory) | 10,000 Splice Data |

| Splice Image Capture (with 8GB SD Card) | 50,200 Images |

| Splice Data Storage (with 8GB SD Card) | 20,000 Splice Data |

| FUNCTION | |

|---|---|

| Splice Auto-Start | Yes |

| Heating Auto-Start | Yes |

| Reversible Coating Clamps | Yes |

| Display of Remaining Splice & Heat Cycles | Yes |

| Dual Automatic Independent Heaters | Yes |

| User-Selectable Heater Clamp Operation | Yes |

| Automatic Fiber Count Detection | Yes |

| ADDITIONAL SERVICES & FUCTIONS | |

|---|---|

| Touch Screen LCD Display | Yes |

| SumiCloud™ Wi-Fi Available (Optional) | Yes |

| Onboard User Training Videos | Yes |

| Remote Interactive Maintenance | Yes |

| TERMINALS | |

|---|---|

| DC Output | DC 12V (for JR-6+) |

| USB Port | USP 2.0 (Mini-B Type) |

| Storage Media | SD/SDHD Memory Card Max 32 GB |

| POWER SUPPLY | |

|---|---|

| AC Input | AC 100 to 240V, 50/60 Hz |

| DC Input | DC 10 to 15 V, 7.5A |

| Battery Pack | Li-ion 10.8V, 6,400 mAh |

| Power Cord (Part Number) | PC-AC2 |

| AC (Part Number) | ADC-16 |

| Battery Pack (Part Number) | BU-102 |

| OPERATION CONDITION | |

|---|---|

| Altitude Range | 0 to 12,007 ft (0 to 3,660 m) |

| Temperature Range | +14 to 122°C (-10 to +50°C) |

| Relative Humidity Range | 0 to 95% HF |

| Wind Velocity | ≤ 33 mph (15 m/sec) |

| STORAGE & SHIPPING CONDITIONS | |

|---|---|

| Temperature Range | -40 to +176°F (-40 to +80°C) |

| Temperature Range (Battery) | -4 to +86°F (-20 to +30°C) |

| Relative Humidity Range | 0 to 95% RH |

| ELECTRODES | |

|---|---|

| Spare Electrodes (Part Number) | ER-10 |

| Electrode Life | 1,500 Arc Discharges |

| ENVIRONMENTAL DURABILITY | |

|---|---|

| Shock Resistance (Excluding Top Face) | Drop 30 in (76 cm) on 5 Faces |

| Impact Resistance Rating (Monitor) | IK07 |

| Water Resistance Rating | IPx2 |

| Dust Resistance Rating | IP5x |

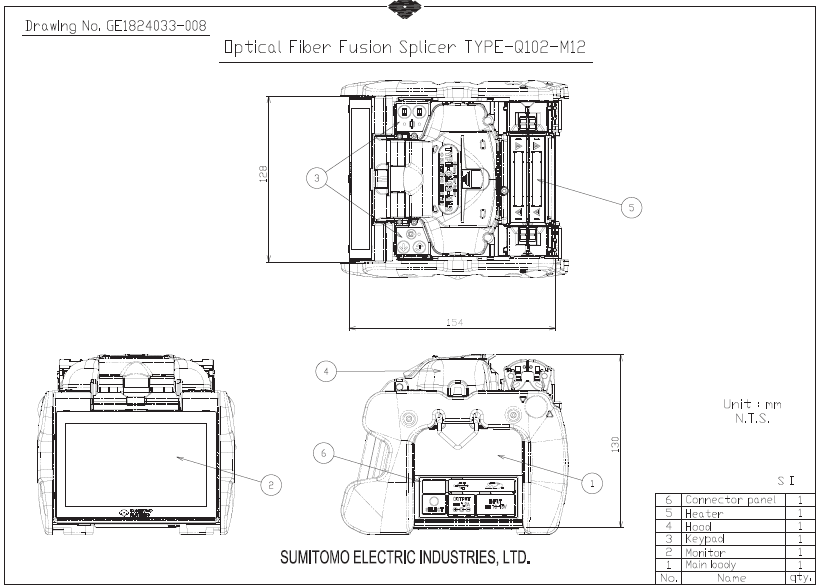

Physical Characteristics

| Height | 5.2 in (130 mm) |

| Width | 5.1 in (128 mm) |

| Depth | 6.1 in (154 mm) |

| Monitor Screen | 5 in (127 mm) |

| Weight (without Battery) | 4.0 lb (1.8 kg) |

| Weight (with Battery) | 4.7 lb (2.1 kg) |

| Hard Transit Case Height | 10.6 in (268 mm) |

| Hard Transit Case Width | 18.7 in (474 mm) |

| Hard Transit Case Depth | 12.3 in (312 mm) |

Technical Drawing

Kitting Components

| COMPONENTS | QUANTITY |

|---|---|

| Hard Transit Case | 1 |

| Battery Unit (BU-10) | 1 |

| AC Adapter | 1 |

| Power Cord | 1 |

| Cleaning Kit (FUS-CLN-KIT) | 1 |

| Mass Splice Protection Sleeves (FPS-6) | 25 |

| Pair of Spare Electrodes (ER-10) | 1 |

| Cooling Tray | 1 |

| Pair of 250 µm 12-Fiber Holders (FHM-12V) | 1 |

| Pair of 250 µm Single Fiber Holders (FHS-025) | 1 |

| Thermal Jacket Stripper (JR−6+) | 1 |

Ordering Information

6S+ Single Fiber Cleaver Kit

PN: TYPE-Q102-M12-KIT-6RM1p

| COMPONENTS |

|---|

| Q102-12M Mass Fusion Splicer |

| Auto Rotating Fiber Optic Cleaver (FC-6Rp) |

| Q102-12M Kitting Components |

6S+ Single Fiber Cleaver Kit & Pitch Conversion Kit

PN: TYPE-Q102-M12-KIT-6RM1p-PCH

| COMPONENTS |

|---|

| Q102-12M Mass Fusion Splicer |

| Auto Rotating Fiber Optic Cleaver (FC-6Rp) |

| Pair of Ribbon Fiber Pitch Conversion Holders (FHM−PCH−12) |

| Q102-12M Kitting Components |

6R+ Rotating Fiber Cleaver & FTA-2 Ribbonizing Kit

PN: TYPE-Q102-M12-KIT-6RM2p

| COMPONENTS |

|---|

| Q102-M12 Mass Fusion Splicer |

| Auto Rotating Fiber Optic Cleaver (FC-6Rp) |

| Fiber Arrangement Tool (FTA-2) |

| Pads & Glue for Ribbonizer (FAC-24) |

| Q102-M12 Kitting Components |

6R+ Rotating Fiber Cleaver & OFA-01 Ribbonizing Kit

PN: TYPE-Q102-M12-KIT-6RM3p

| COMPONENTS |

|---|

| Q102-M12 Mass Fusion Splicer |

| Auto Rotating Fiber Optic Cleaver (FC-6Rp) |

| Fiber Arrangement Tool (OFA-01) |

| Q102-M12 Kitting Components |

6R+ Rotating Fiber Cleaver & Lynx MPO Splice-On Kit 1

PN: TYPE-Q102-M12-KIT-MPO1p

| COMPONENTS |

|---|

| Q102-M12 Mass Fusion Splicer |

| Auto Rotating Fiber Optic Cleaver (FC-6Rp) |

| Lynx Carrying Bag |

| Pair of 12-Fiber Lynx MPO Metal Holders (FHM-12-MPO-MTL) |

| Lynx Sheath Splitter for 2 to 3 mm Cords (LYNX2-CORDTOOL-2.0-3.0) |

| Lynx Aramid Shears (LYNX-SHEARS) |

| Assembly Platform for Lynx MPO with Ribbonizer (LYNX2-ATK2-MPO) |

| Glue for Ribbonizer (FAC-24-003A) |

| Q102-M12 Kitting Components (No Battery) |

6R+ Rotating Fiber Cleaver & Lynx MPO Splice-On Kit 2

PN: TYPE-Q102-M12-KIT-MPO2p

| COMPONENTS |

|---|

| Q102-M12 Mass Fusion Splicer |

| Auto Rotating Fiber Optic Cleaver (FC-6Rp) |

| Lynx Carrying Bag |

| Pair of 12-Fiber Lynx MPO Metal Holders (FHM-12-MPO-MTL) |

| Lynx SOC Card Prep tool (LYNX2-CORDTOOL-2.0-3.0) |

| Lynx Aramid Shears (LYNX-SHEARS) |

| Assembly Platform for Lynx MPO with Ribbonizer (LYNX2-ATK2-MPO) |

| Pads & Glue for Ribbonizer (FAC-24) |

| Q102-M12 Kitting Components |

8R Rotating Fiber Cleaver Kit

PN: TYPE-Q102-M12-KIT-8RM1

| COMPONENTS |

|---|

| Q102-12M Mass Fusion Splicer |

| Auto Rotating Fiber Optic Cleaver (FC-8R) |

| Q102-12M Kitting Components |

8R Rotating Fiber Cleaver Kit

PN: TYPE-Q102-M12-KIT-8RM2

| COMPONENTS |

|---|

| Q102-M12 Mass Fusion Splicer |

| Auto Rotating Fiber Optic Cleaver (FC-8R) |

| Fiber Arrangement Tool (FTA-02) |

| Pads & Glue for Ribbonizer (FAC-24) |

| Q102-M12 Kitting Components |

Accessories

| PART NUMBER | DESCRIPTION |

|---|---|

| FPS-6-5P | Mass Fiber Protection Sleeves, 1.57 in (40 mm). 5 per pack. |

| FPS-6 | Mass Fiber Protection Sleeves, 1.57 in (40 mm). 25 per pack |

| FPS-6-BX | Mass Fiber Protection Sleeves, 1.57 in (40 mm). 250 per pack |

| FHM-12V | Pair of 12 Fiber Ribbon V Shaped Holders for 250 um Fibers |

| FHM-PCH-12 | Pair of 12 Fiber Ribbon Pitch Conversion Holders for 250 um Fiber |

| FHM-12N | Pair of 12-Fiber Ribbon Holders for 200 um Fibers |

| FHM-10 | Pair of 10-Fiber Ribbon Holders for 250 um Fibers |

| FHM-8 | Pair of 8-Fiber Ribbon Holders for 250 um Fibers |

| FHM-6 | Pair of 6–Fiber Ribbon Holders for 250 um Fibers |

| FHM-4 | Pair of 4-Fiber Ribbon Holders for 250 um Fibers |

| FHS-09 | Pair of Single Fiber Ribbon Holders for 900 um Fibers |

| FHS-025 | Pair of Single Fiber Ribbon Holders for 250 um Fibers |

| FHS-200 | Pair of Single Fiber Ribbon Holders for 200 um Fibers |

| BU-102 | Battery Pack, Li-ion 6,400mAh |

| BC-102 | Battery Charger for BU102 |

| ER-10 | Replacement Electrodes |

| WLSD-0416 | SumiCloud™ Connection |

Features

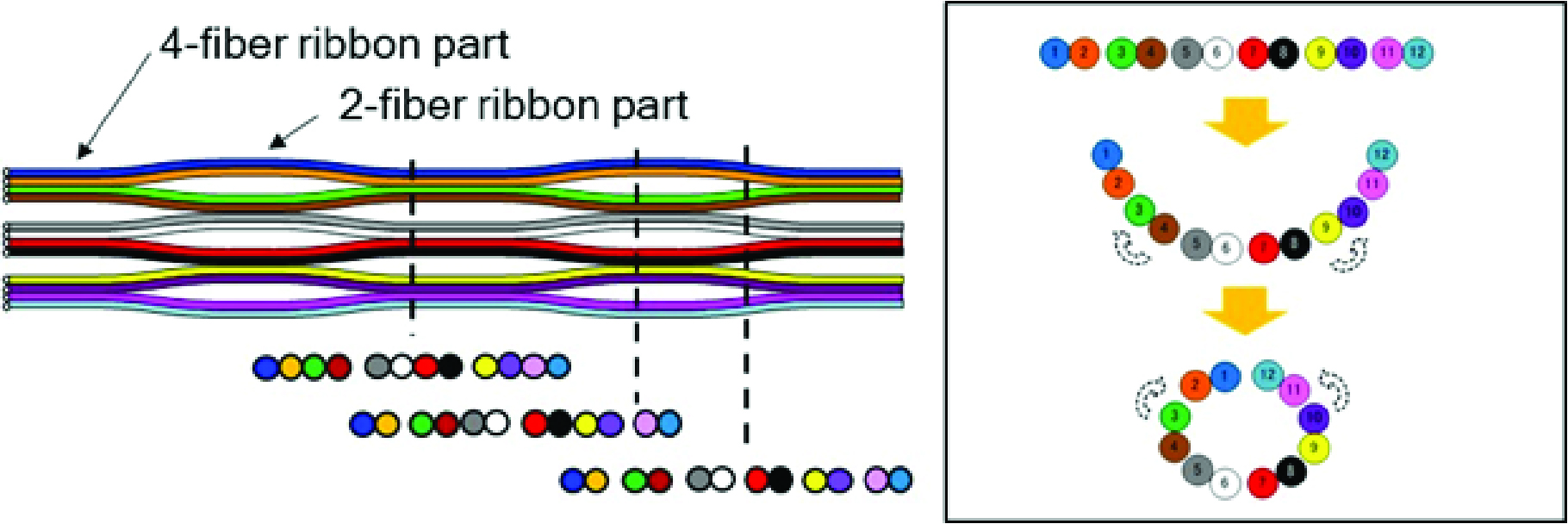

Pliable Freeform Ribbon™

The new Type-Q102-M12 is accompanied with new features and benefits capable of deploying next-generation hyperscale networks. Consistent and quality low-loss splicing, the compatibility with Lynx-CustomFit™ Splice-On Connectors, and Sumitomo Electric’s patented dual independent ovens make this fusion splicer a preferred choice for extensive and diverse optical fiber networks. The new ribbon fiber splicer is adaptable to 250 µm and 200 µm ecosystems, and has a wide range of accessories for various ribbon fiber splicing situations.

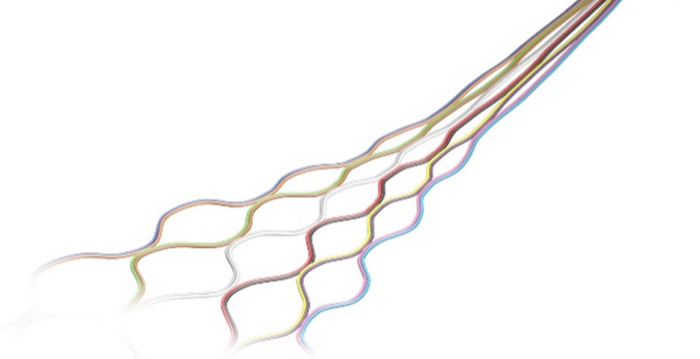

Pliable Freeform Ribbon™

SEL’s patented 12 fiber ribbons provides the ability to move in any direction without breaking, and more condensed fiber in a small diameter cable.

Additional Features

- Auto Clamping Adjustment System “Active-ACAS”

- Automatic Fiber Count Detection

- Patented Duel Automatic Independent Heaters

- 5 in (127 mm) TFT Colored Touch Screen Display

- Shock (Drop from 76 cm on 5 Faces), Water (IPX2), and Dust Resistance (IP5X)

- Preventive Maintenance & Software Upgrades Supported by SumiCloud

- Auto Clamping Adjustment System “Active-ACAS”

- Automatic Fiber Count Detection

- Patented Duel Automatic Independent Heaters

- 5 in (127 mm) TFT Colored Touch Screen Display

- Shock (Drop from 76 cm on 5 Faces), Water (IPX2), and Dust Resistance (IP5X)

- Preventive Maintenance & Software Upgrades Supported by SumiCloud