One of the key challenges currently facing the data center industry is the exponential growth of data generation. Digital transformations such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT) are placing unprecedented demands on connected network infrastructure. To meet these challenges, data centers must be able to scale quickly and cost effectively while reducing space and power usage. As networks evolve, so does the hardware that forms the foundation of those networks. Advanced fiber optics are the backbone of a data center’s system infrastructure. Data centers require high-density solutions to maximize existing space for ducts, cables, racks, and more. In response, Sumitomo Electric Lightwave (SEL) has developed the technology to outfit these networks for high-volume facilities: Ultra-High-Fiber-Count (UHFC) Cable. UHFC is a high-density optical-fiber cable designed to meet the need for the increased transmission capacity of data centers. With high-density and smaller-sized cable like SEL’s UHFC, massive data capacity can be installed all at one time while saving limited space in ducts.

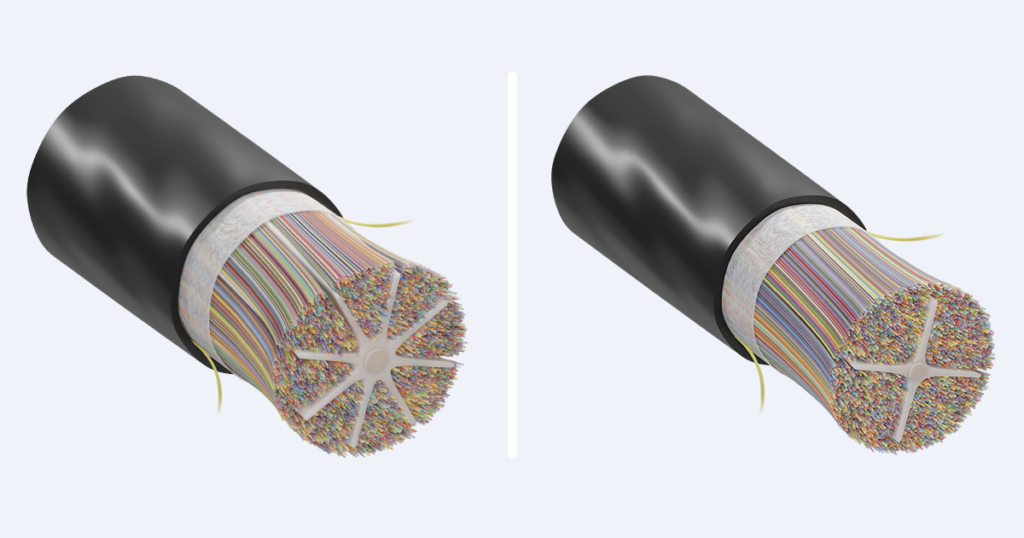

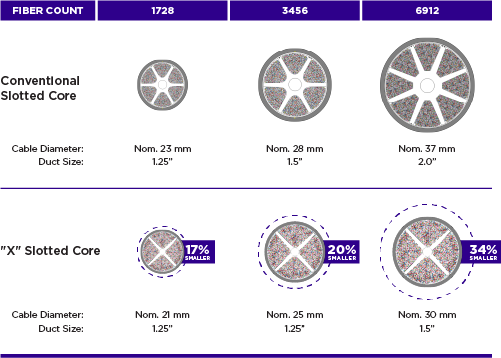

First introduced by SEL in 2017, the 6912-fiber-count cable consisted of the highest number of fibers in the world at that time and has maintained that distinction (in commercial use). In responding to continuous and increasing demand for higher transmission capacity in limited space, SEL developed UHFC with a diameter reduced from 37mm (suitable for 2” duct) to 30mm, suitable for 1.5” duct. Compared to conventional cable, the new 6912-fiber-count cable is 23% lighter in weight and 34% smaller in cross-sectional area, and the maximum length per drum is 50% longer. This improves ease of installation and reduces both the number of materials used as well as requires less transportation energy. In order to reduce diameter, the area in which fibers can be packaged has been expanded inside the cable by reducing the number of grooves but keeping the high mechanical strength.

UHFC is designed with structure optimization combined with Freeform Ribbon™ technology, providing benefits which include space savings, higher density, faster installations, lower installation and support costs, reduced environmental effects, and the flexibility to change. This pliable 12-fiber ribbon combines the easy workability of mass-fusion splicing with ribbon flexibility. It allows for dense fiber packing and a small cable diameter, which increases density in areas like space-constrained data centers.

Learn more about the Benefits of Dense Fiber Packing with Freeform Ribbon™ Technology.